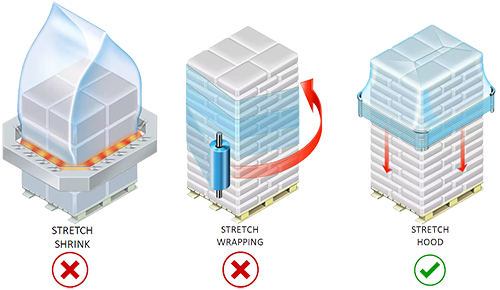

Our Pallets are damaged during Transportation, does stretch hooder Solve it ?

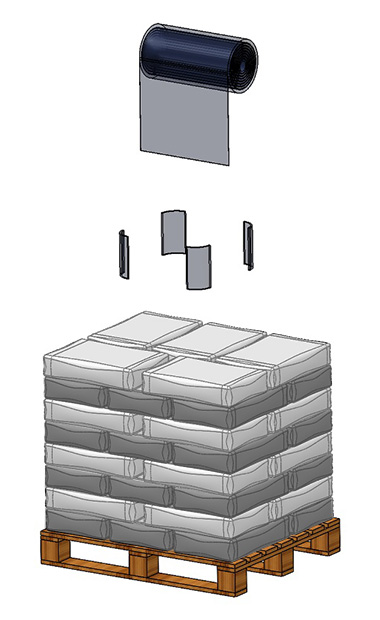

Yes, Stretch Hooder gives extra strength to your Pallet by stretching film

It makes your pallets more steady and durable

Which Products can be stretched by Stretch Hooder ?

It can be applicable to many sectors such as chemicals, minings, ceramics, minerals, beverages, food, feed, seeds , bricks, etc...

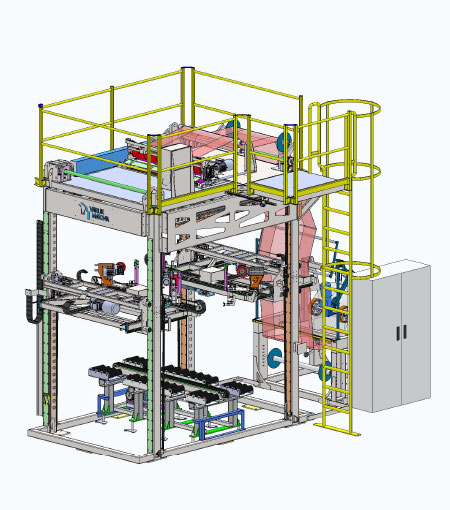

What is the capacity for Stretch hooder?

You can get 50-120 Pallets per Hour

What is the max High For Pallet ?

As a standart , 1600mm (1,6mt) , but also different high are available, suc as 1,8mt -2,0mt and 2,2mt

What is the stretch Film thickness ?

It may vary according to Stretch Film quality , Genarally between 80-120 Micron

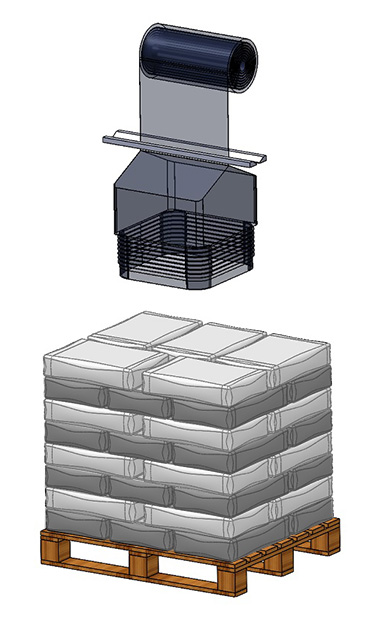

Can I use same Film Roller for two different pallet Sizes ?

According to Stretch film Producers catalogues , you can stretch /use One roller size for different size of Pallets. Detail information can be obtain from stretch film Producers.

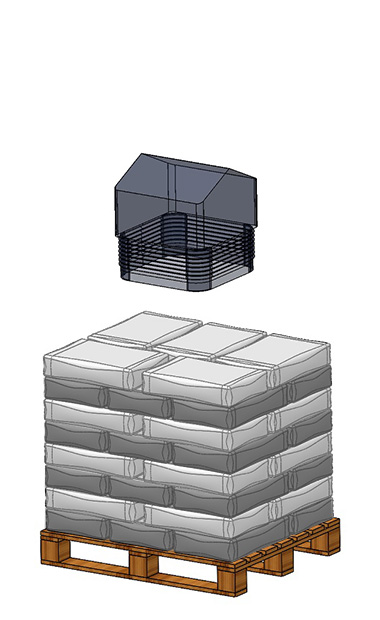

What pallet sizes can be used ?

You can use several Pallet sizes , such as 80x120 cm , 100x110 , 110x110 , etc..

You can use also different Pallet sizes

Should I make adjustment For Different Pallet High ?

No; Machine measure the high of the Pallet automatically and arrange film length accordingly

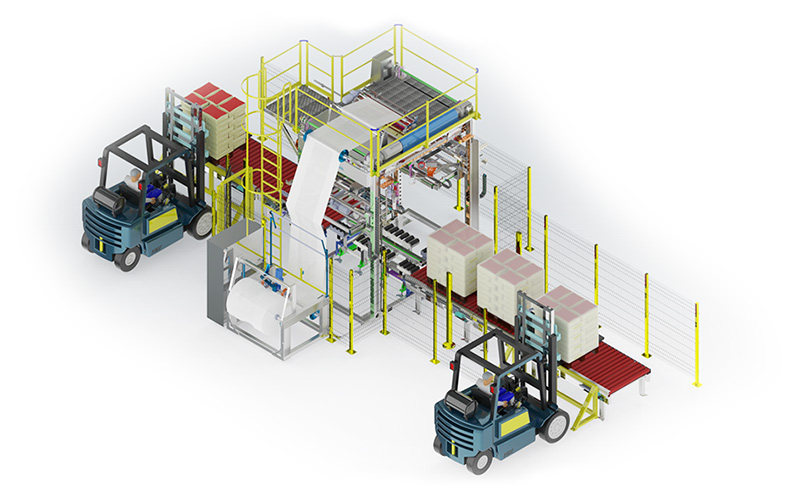

If forklift operator would not take the full pallets from the machine , What Happens?

According the your storage conveyor quantity , it will store on the roller conveyors,

When all the storage roller conveyors full , it will finish stretching process on the center conveyor and it will wait till operator takes stretched Pallets

Is it Possible to acces remote and support the technicians?

Yes , if requested with your permissions, we can Access to machine , we can check the programming and diagnose the troubleshoot.

We can also revise the program of the stretch hooder remotely , such as a new conveyor integrations, shuttle conveyor integrations etc...

If the Stretch Hooder connected to Auto palletizer , is it available to feed External Pallet to stretch hooder while palletizer in Running mode?

Yes , we install Side feding conveyor with safety Light barriers.

Once Forklift entered to put External Full pallet to "stretch hooder" inlet roller conveyor , light safety barrier will Pause the previous conveyor and Palletizer consecutively

When operator leave the Conveyor , he push the button where is next to conveyor , and system continue automatically.

Where can I supply Stretch Hooder Films ?

Around the World , Many stretch film producers also produce stretch hooder films.

How can I suply Spare Parts ?

You can contact to Varlik Makina,

You can select the spares from manuals , All the spares are available.